Technologies

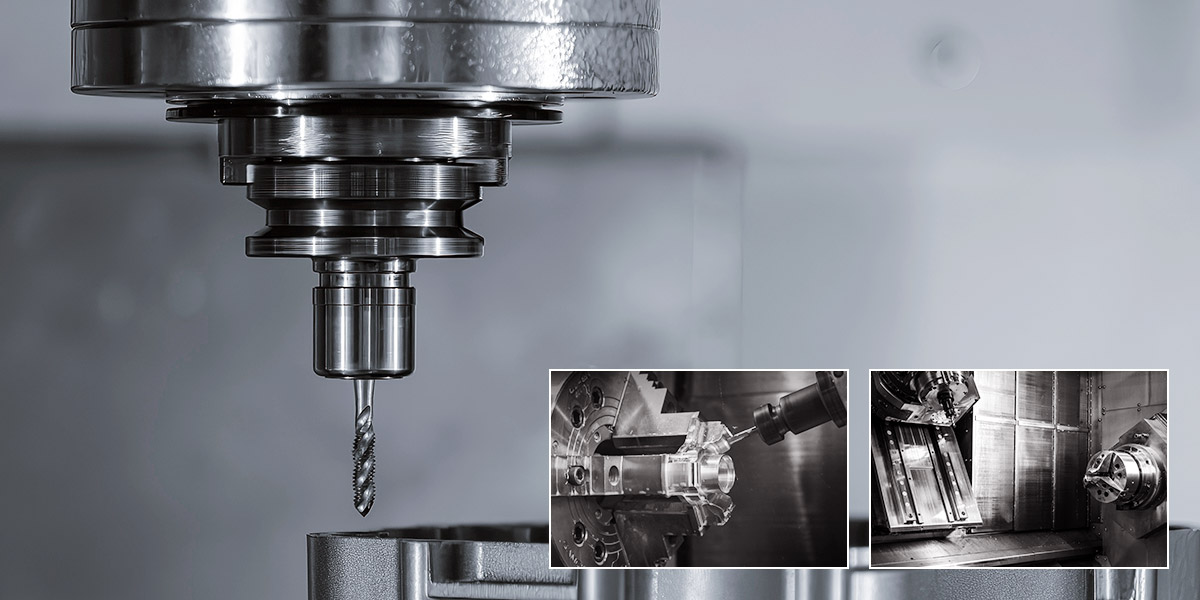

Precision Machining MCT, CNC

The metal components of SGEAR products are manufactured through highly precise machining processes. Multi-axis machining using MCT (Machining Center) enables the machine to create complex shapes in a single operation, unlike CNC (Computer Numerical Control) machining, which requires manual repositioning each time the direction changes. As a result, MCT offers higher precision, allowing for minimal gaps between parts and enabling the construction of more robust supports.

Design, machining, and assembly are all conducted within the same SGEAR facility. This in-house integration allows us to customize specifications to meet a wide range of client requirements. Dimensions, length, load capacity, and other parameters can be flexibly adjusted while maintaining a high level of precision.

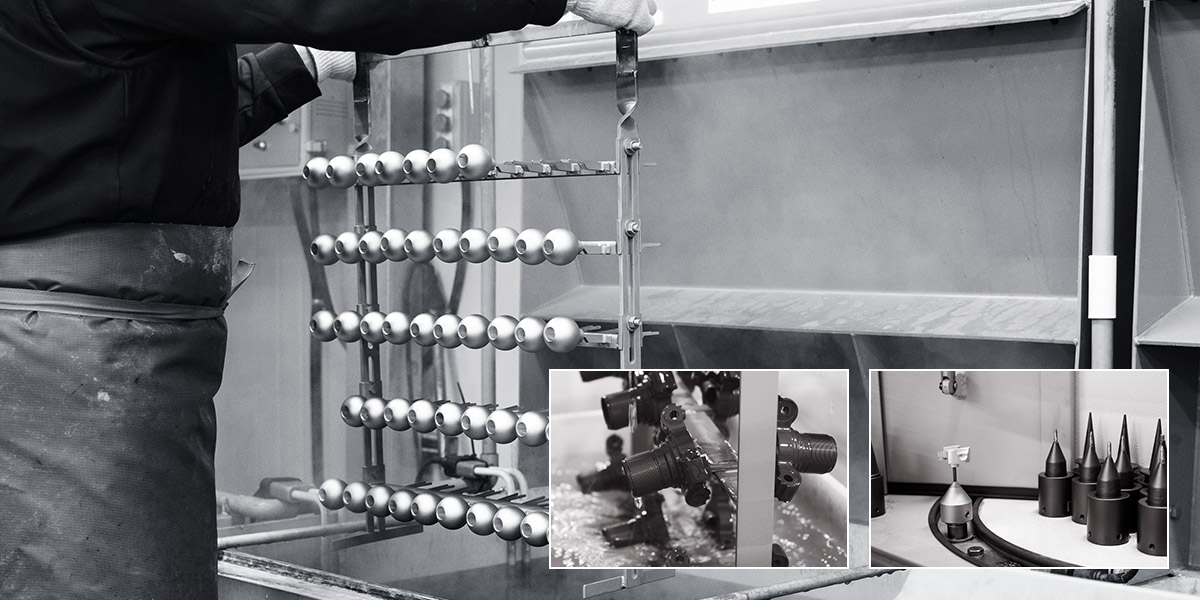

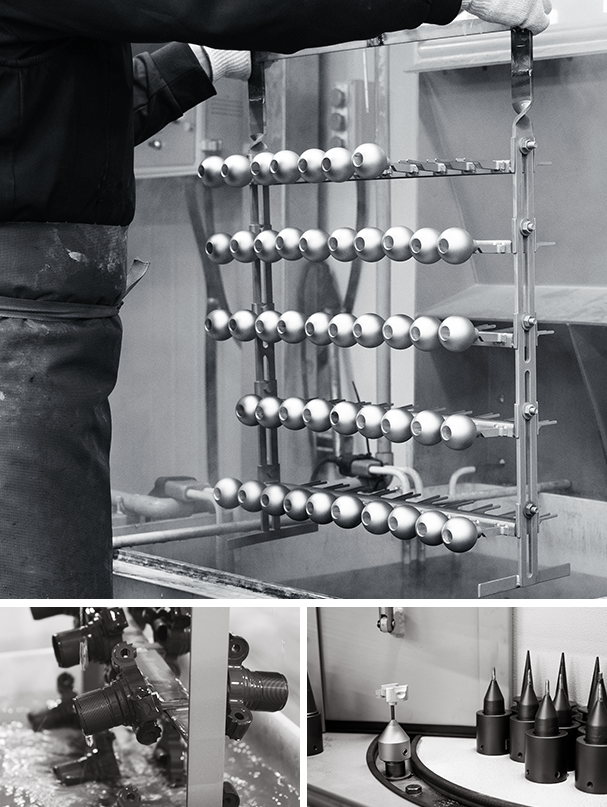

Low-Temperature Hard Anodizing

Aluminum is lightweight, durable, and easy to machine, making it an ideal material. However, due to its relatively low surface hardness, anodizing treatment is essential to enhance its durability. Anodizing not only adds color to the surface of aluminum but also increases its hardness, significantly improving the overall strength of the product.

SGEAR applies a low-temperature hard anodizing process conducted below freezing temperatures. This method is more complex and challenging than standard anodizing but results in a thicker and harder oxide layer. The resulting aluminum oxide layer ranges from approximately 0.7 to 3mm, greatly increasing surface hardness.

Before the anodizing process, SGEAR performs barrel polishing and sanding to smooth out sharp edges, resulting in a more refined finish and softer corners. The deep gray color of our products is a natural result of the low-temperature hard anodizing process.

SGEAR applies a low-temperature hard anodizing process conducted below freezing temperatures. This method is more complex and challenging than standard anodizing but results in a thicker and harder oxide layer. The resulting aluminum oxide layer ranges from approximately 0.7 to 3mm, greatly increasing surface hardness.

Before the anodizing process, SGEAR performs barrel polishing and sanding to smooth out sharp edges, resulting in a more refined finish and softer corners. The deep gray color of our products is a natural result of the low-temperature hard anodizing process.

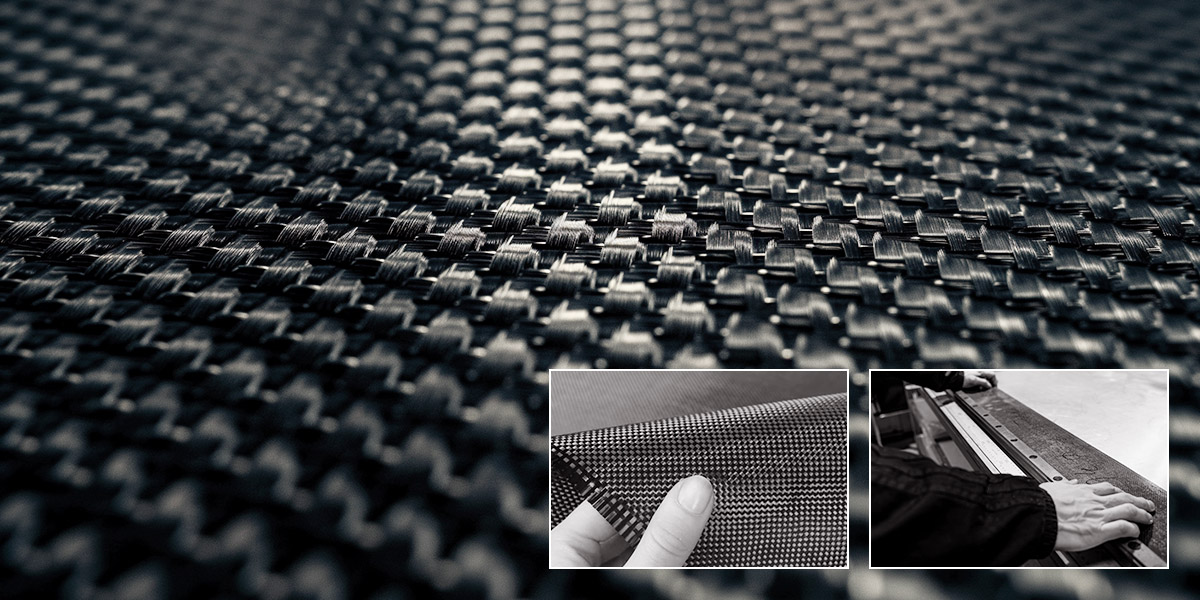

High and Ultra-High Modulus Carbon Fiber

Carbon fiber is a cutting-edge material that is lighter than aluminum and as strong as steel. It resists deformation even in high-humidity environments, making it highly reliable under various outdoor conditions. The carbon fiber tubes used in SGEAR’s support systems are made with 40t/mm² high-modulus and 65t/mm² ultra-high-modulus carbon sheets, offering exceptional load-bearing strength. Higher modulus carbon fabrics support greater weights and absorb vibrations more effectively.

Carbon fiber pipes in SGEAR tripods quickly suppress vibrations from attached equipment. This rapid stabilization is critical in minimizing disturbances caused by wind, ground movement, or equipment operation. SGEAR possesses the advanced expertise required to manufacture these carbon pipes using high-modulus materials. Building on this proprietary technology, we precisely control the tolerances between carbon and aluminum components to deliver tripods with unmatched stability.